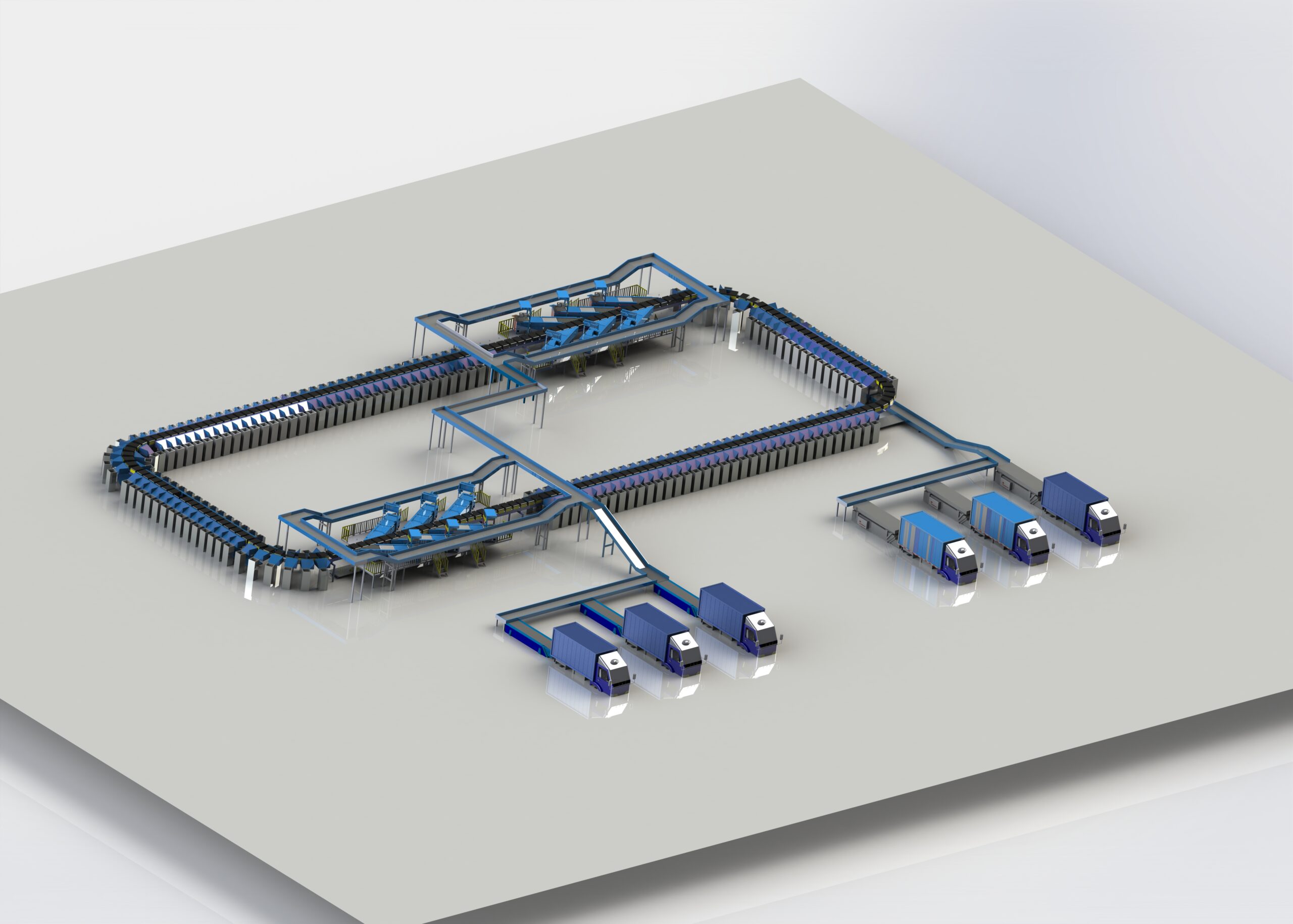

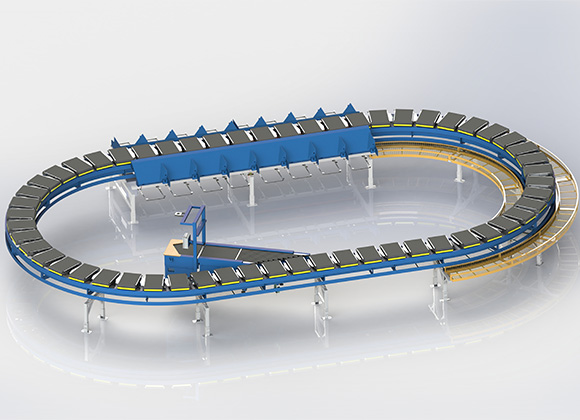

Cross belt sorting system is a highly flexible, functionally stable, and highly reliable cross belt sorting system. It’s composed of the belt conveyor, loading platform, sorting carrier, code reading and weighing system, coding system, and bagging system. It has been widely used in large-batch parcel conveying and sorting over long hours, often seen in warehousing and express centers.

Talk To An Engineer

The twin cell cross belt sorter is an upgrade product based on the need for mixed sorting of large and small packages, and the size of the sorting package can be increased from 400*600*400mm to 800*600*400mm.

Learn More

Running speed up to 2.5m/s

handle up to 18,000 pcs/h for single layer single zone

Error rate under 0.01%

Our new system can be seamlessly integrated into your existing lines or sorting equipment.

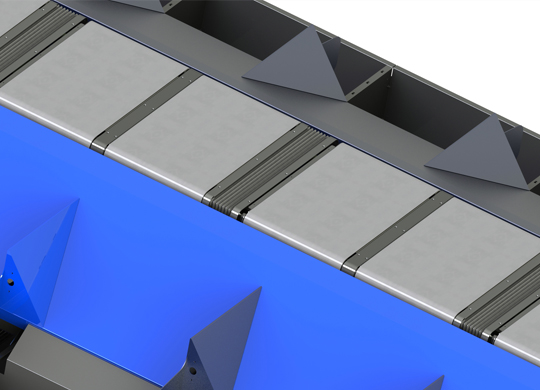

Adopting the non-contact sorting technology, your goods on the sorter will stay safe and sound.

Modular in design, our cross belt sorter features high flexibility in installation and expansion.

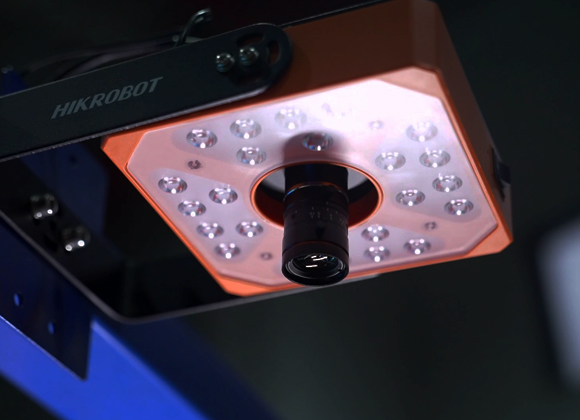

Articles are set one by one onto the loading conveyor and then scanned and weighted.

After scanning and weighing, the parameters of the package are corrected through high-precision light curtain measurement and 3/4-servo control, and the package is accurately loaded to the center position of the carrier.

According to the barcode information obtained by scanning the code, the parcel will be sorted to the right destination.

When a container becomes full, the indicator light turns red and emits a buzzer. Hang the new container on the pole, and make sure that the chute number corresponds to the container number.

Cross belt sorter works perfectly for various industries including parcel express, postal, e-commerce, warehousing, etc. It can sort packages of different sizes.