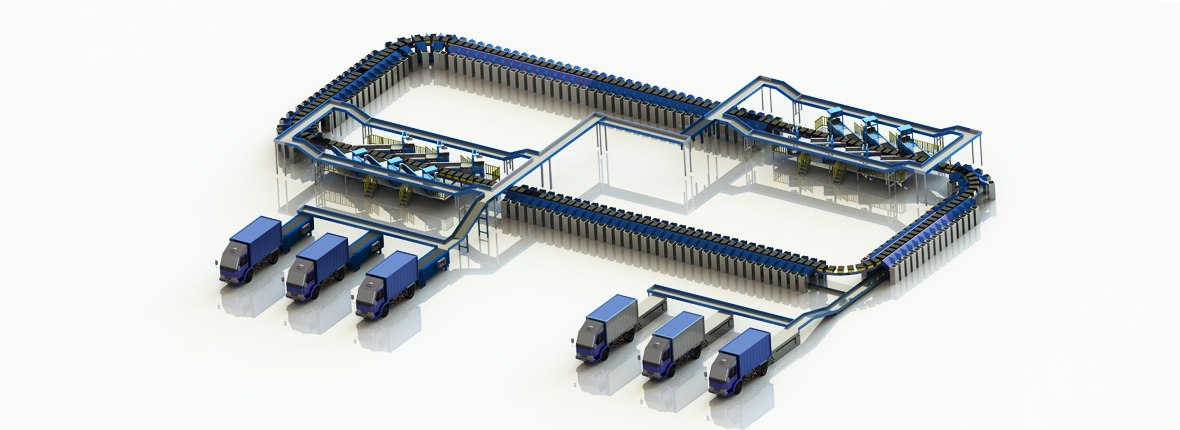

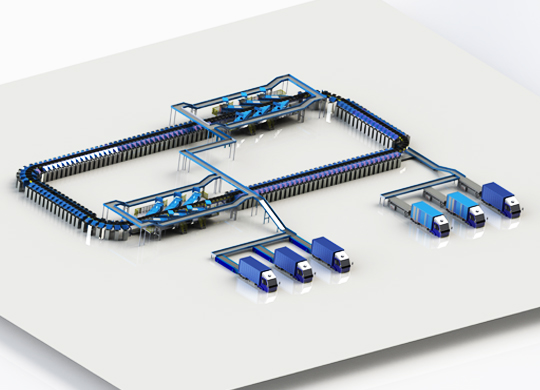

The circular cross belt sorting system is a highly flexible, functionally stable, and highly reliable cross belt sorting system. It’s composed of the belt conveyor, loading platform, sorting carrier, code reading and weighing system, coding system, and bagging system. It has been widely used in large-batch parcel conveying and sorting over long hours, often seen in warehousing and express centers.

According to the product structure, the sorter is classified as conventional circular cross belt sorter, small & big track double-layer cross belt sorter and single track double-layer cross belt sorter.

Conventional circular cross belt sorter: single-layer and multi-layer configurations available; the multi-layer height difference is 1,200mm, and each layer has independent operation control.

Small & big track double-layer cross belt sorter: the height difference between upper and lower layers is 800mm, and upper track has simple configuration, relying on the operation of the lower layer to help the upper layer.

Single track double-layer cross belt sorter: the height difference between upper and lower layers is only 600mm, only requireing one-layer power supply communication to achieve double-layer sorting.

According to different sizes of packages, provides small package sorter and big-small package sorter.

Small package sorter: which can sort the package size up to 600*400*400mm.

Big-small package sorter: twin cell sorter that can sort the packages up to 800*600“400mm.

Book a consultant now and we will get back to you within 24 hours.

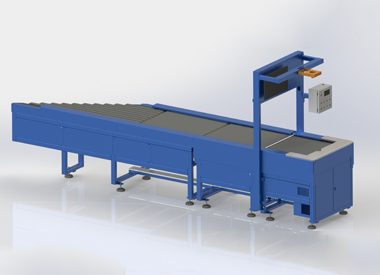

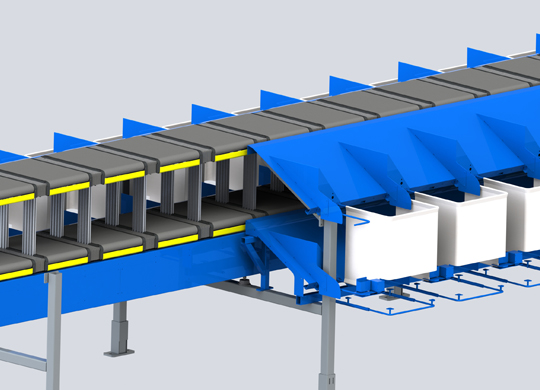

Parcel scanning supports parcel infeed scanning and loop line top scanning. Parcel infeed scanning: the parcel passes through 4 secfions-scanning, weighing, caching and accelerating, through the parcel infeed to improve the weighing accuracy and infeeding efficiency significantly with the optimization algorithm. Loop line top scanning: after being weighed, cached, and accelerated through the parcel infeed, the parcel enters the loop line for scanning, segmentation, and efficient misclassification reduction.

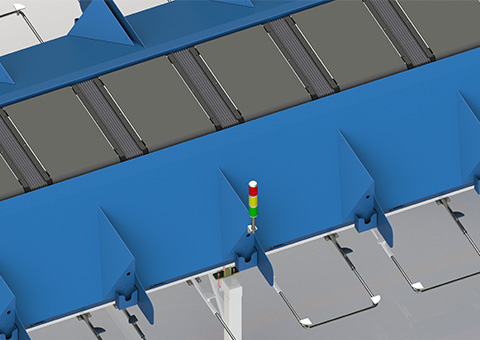

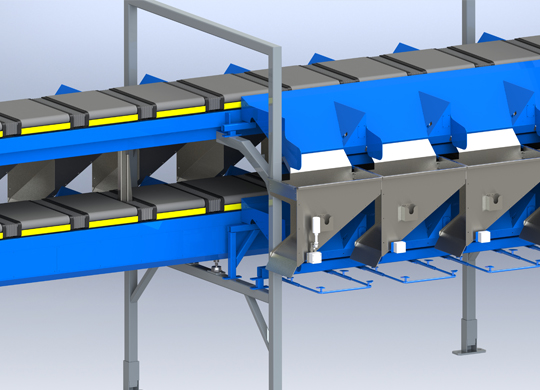

The unique chute design can accurately control the outfeeding position and speed.

Center and detect parcels on the cart to reduce floating and misclassification. The deviation-rectifying camera automatically detects whether the parcel on the cart is in the center, and performs rectifying on the parcel out of position. In addition, when more than one parcel detected on a single cart, the system will automatically classify them as abnormal and send them to the abnormal chute.

Support parcel infeeding efficiency, operator performance, bag changing time, overall sorting capacity, misclassification data real-time statistics and cause analysis, user information system platform docking and other functions. According to customer requirements, it can customize and develop OCR, parcel infeed, unmanned parcel infeeding scanning software, as well as complementing code, post and express co-distribution, customer-parcel information fusion software and systems, so that it can meet the needs of various scenarios such as distribution center, parcel depots, and multi-express brand co-distribution.

Contact our experts for a detail specsheet. Provide us with your email address and we will send you the file once we verify it an authentic request.

Get The Technical ManualConfirmWare offers different types of sorters to meet your sorting needs.

Single-layer and multi-layer configurations available; the multi-layer height difference is 1,200mm, and each layer has independent operation control.

The height difference between upper and lower layers is 800mm, and upper track has simple configuration, relying on the operation of the lower layer to help the upper layer.

The height difference between upper and lower layers is only 600mm, only requireing one-layer power supply communication to achieve double-layer sorting.

|

Specifications |

Parameters |

| Running Speed |

2.5m/s |

|

Sorting Capacity |

12000-18000 PPH Single layer single zone |

| Drive system |

5.5kW Linear motor |

|

Cart pitch |

600mm/1100mm |

| Cart length |

700mm |

|

Cart belt width |

430mm |

| Parcel infeed mode |

Semi-automatic parcel infeed |

|

Core components |

Specifications | Parameters |

| Fully-automatic/semi-automatic parcel infeed | Parcel infeeding capacity |

2700PPH |

|

Code reading mode |

Static scanning on parcel infeed/loop line 5-side high-speed scanning (optional) | |

| Power |

1.5kW Servo motor*4 |

|

|

Max dimensions of goods |

400mm*600mm*800mm | |

| Measuring mode |

Measuring light curtain |

|

|

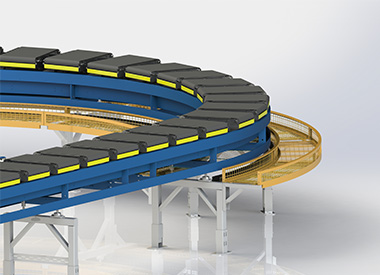

Traveling track |

Curve section centre radius | 3.4m |

| Track material |

3mm metal plate |

|

|

Surface treatment |

Spray coating | |

| Drive mode |

Linear motor+redundancy |

|

|

Sorter |

Pitch | 600mm/700mm/1100mm |

| Cart length |

700mm |

|

|

Belt width |

430mm | |

| Max load of single cart |

5kgs |

|

|

Sensor |

Loop line position detection | Photoelectric sensor |

| Empty cart detection |

Camera/photoelectric detection (optional) |

|

|

Parcel detection |

Optional | |

| Power supply/communication mode | Power supply mode |

Panasonic tro-reel HS |

|

Communication mode |

RCoax cable communicacon | |

| Chute | Pitch |

700/750/1200mm |

|

Chute length |

755mm | |

| Chute angle |

30° |

|

|

Material |

2.5mm metal plate | |

| Bag frame | Bag holder |

450*500mm |