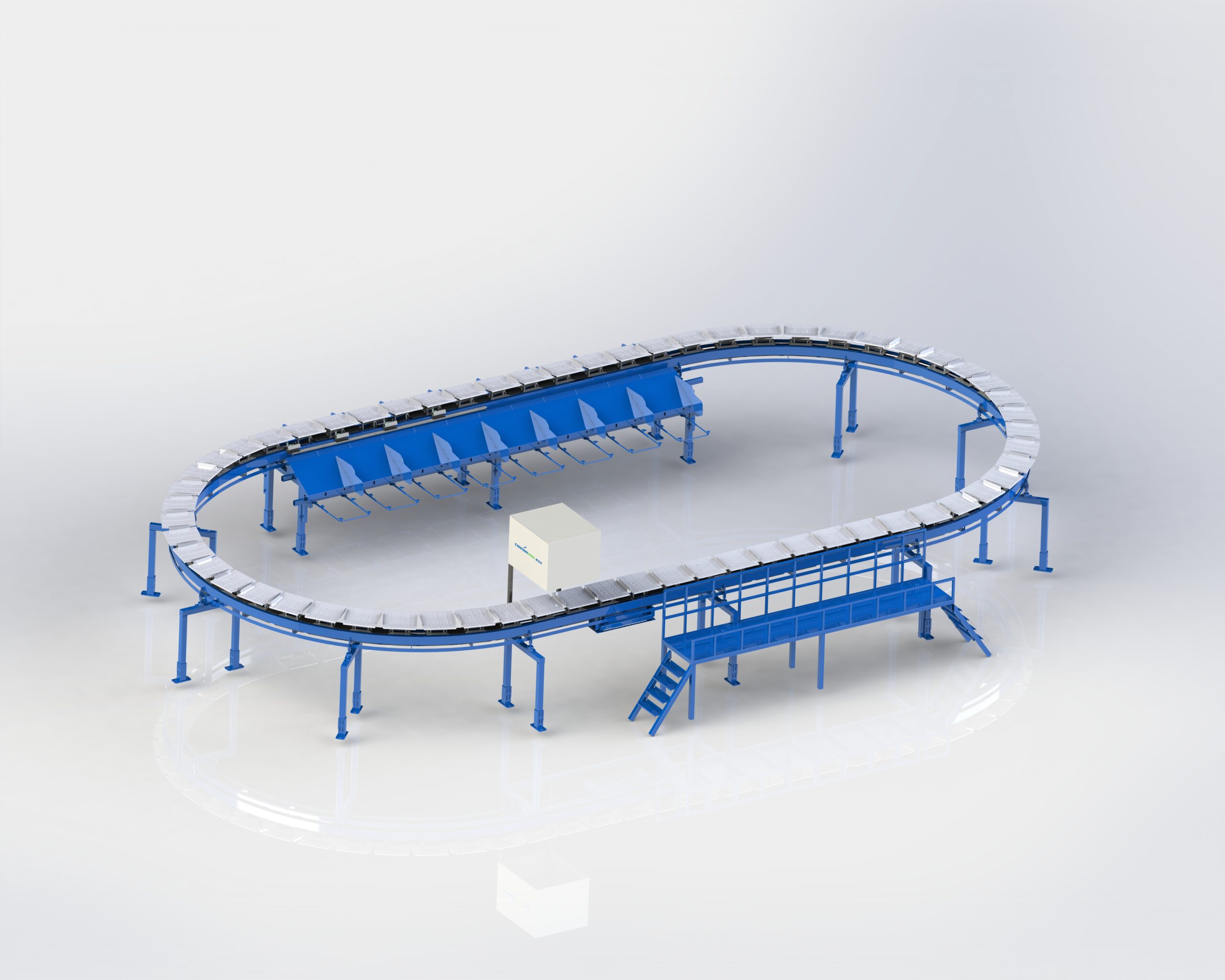

The tilt-tray sorting System is an automated sorting equipment designed specifcally for irregular-shaped items. lt consists of traystilting devices,identification, and conveying systems, available in single-sided and double-sided tilt options, With compact overal structure,small footprint, efficient and fexible sorting process.

Talk To An Engineer

Our tilt tray sorter sorts more types of packages than all other sorters.

The items can be discharged either side to their right destination.

The modular design with fewer moving parts takes a shorter period for installation.

Compared to other sorters, a tilt tray sorter features the lowest noise level.

|

Model |

Single-sided | Double-sided |

|

Running speed |

1-1.5m/s | |

|

Sorting capacity |

7200-10800PPH |

|

| Weight range of package |

0-7kg |

|

| Chute width |

700/750/1000mm(可定制) |

|

|

Misclassification rate |

≤0.01% | |

| Dimension range of package |

W50mm*L20mm*H2mm-W500mm*L400mm*H400mm |

W50mm*L20mm*H2mm-W500mm*L600mm*H400mm |

|

Tray pitch

|

400/500mm | 500/600mm |

| Tray size | 400mm*380mm*65mm-500mm*420mm*65mm |

500mm*420mm*65mm-600mm*520mm*65mm |