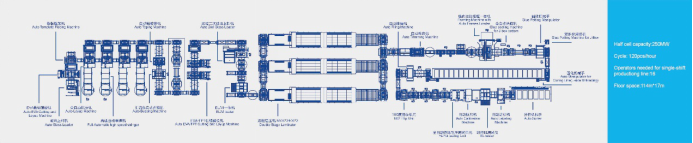

Photovoltaic Automation Knowledge Base - Module Automation Production Line

Photovoltaic cell module is the core part of photovoltaic power generation system, and its function is to convert solar energy into electric energy, in the manner of DC power generation. Then the inverter is used to convert DC power into AC power, which is applicable to our daily use.

The manufacture of photovoltaic modules involves such processes as string soldering, layup, lamination, framing, testing and cleaning etc. Most processes in the early module factories were conducted manually, with inferior production efficiency and low product yield, resulting in increased module price and high cost of the overall photovoltaic power generation system. After years of efforts by automation manufacturers, most of the processes have been updated to fully automated or semi-automated production, and even a number of factories have first been transformed into the "Dark Factory" to completely realize unmanned manufacturing.

The followings are the core automation equipment for the manufacturing process of photovoltaic module assembly.

Stringer: One of the core equipment in photovoltaic module manufacturing automation system. The stringer can connect positive electrodes and negative electrodes of a plurality of solar cells in strings with each other through the PV ribbon (interconnection ribbon) to form a cell string. According to the different technological routes of cell, there are many kinds of string soldering machines, and the common ones on the current market are conventional stringer, MBB stringer, singled cell stringer and so on.

Glass Loader: It is used to automatically strip the insulating film of the photovoltaic glass, and transport the glass to the predetermined position.

EVA cutting and laying machine: It is used to automatically complete the extending and cutting of EVE, and lay the EVA film onto the upper surface of photovoltaic glass.

Layup machine: The cell strings output by the stringer are aligned and arranged in parallel, usually 6 strings as a group.

Automatic TamingMachine: It is used for automatic completion of high-temperature adhesive tape laying and pasting, to fix the cell string spacing.

Template placing machine: If the photovoltaic production line is not equipped with the auto bussing machine, the template placing machine is used to place the template printed with soldering indication sign to the predetermined position to instruct the workers to perform bus bar soldering.

Auto bussing machine: The PV ribbon (bus bar) is used to complete the parallel circuit connection between the cell strings, thus forming the current loop of the whole module. The auto bussing machine can automatically complete the functions of pulling, positioning, deviation correction and soldering of the bus bar, realizing high degree of automation.

Laminator: It is used to draw out the air from the laid module, apply pressure and heat to melt EVA, and bond the cell, glass and back sheet together. Lamination is also one of the most important processes in photovoltaic module production, and the lamination quality is directly related to the module quality.

Automatic trimming machine: It is used to trim the laminated modules and remove the extra edge materials.

Glue dispensing and framing machine: It is used to install photovoltaic glass to the four sides of the module after glue is dispensed for its applying to the photovoltaic glass frame.

J-box soldering machine: It is used to automatically complete the positioning, installation and soldering of the terminal box.

Testing devices: They are used to complete the testing procedure from cell to module, such as appearance testing, electrical performance testing, which are related to unaligned cell detection, EL detection, etc.

Conveyors: They are used to carry out the conveying of modules and accessories in the production process.

After many years of development, the photovoltaic module manufacturing industry has realized automatic production for most processes, leaving only a small part of manual monitoring assistance. As the technologies are continuously being updated, the degree and speed of automation will be further improved, leading to the cost reduction and efficiency increase of photovoltaic industry.