Photovoltaic Automation Knowledge Base - Stringer

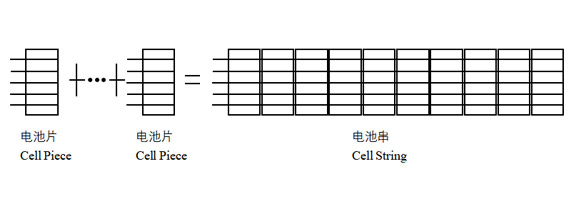

In the manufacturing and assembling process of the photovoltaic module, the positive electrode and the negative electrode of a single piece of photovoltaic cell are required to be connected with each other to form a conductive path, and then the module capable of generating electricity is finally manufactured through the process of layup, lamination and others.

The soldering of photovoltaic cells refers to the process of connecting several positive electrodes and negative electrodes of cells in series through PV ribbon (bars bar ribbon) to form a cell string, and then connecting several strings (usually 6 strings) in parallel through PV ribbon (bussing) to finally form a competed photovoltaic module. Soldering is one of the important processes in photovoltaic module manufacturing, and the soldering quality is directly related to a series of key indexes such as power generation capacity and service life of the module.

The soldering of early photovoltaic cells was conducted manually, so the soldering quality was seriously affected by personal technical level, and the production capacity was low. After several years of development, the automatic stringer technology has become very mature, and according to different cell technologies, a variety of corresponding stringers have been developed. The ones which are widely used at present mainly include the following:

Conventional 4-6BB(bars bar)cell string soldering machine: It is used for the soldering of conventional 4-6BB(bars bar) photovoltaic cells, which are connected by a tin-plated copper flat interconnection ribbon with a width of 0.6-1.2 mm according to the number of bars bar. The main procedures of the stringer include pulling / cutting PV ribbon, laying, positioning and rectification, soldering and detection, etc.

MBB Cell Stringer: It is used to solder 9-16 circular interconnection ribbons with a diameter of about 0.38 mm to photovoltaic cells with a corresponding number of bars bar. Its working principle is basically consistent with that of the conventional stringer.

Singled Cell Stringer: Singled Cell Stringer integrates such technologies as laser cutting, screen printing and laser soldering. Conductive adhesive can be used to realize the imbricating and pasting of positive and negative electrodes of cell pieces, so as to form cell string after curing.

CF conductive adhesive stringer based on back contact technology: CF conductive adhesive stringer based on back contact technology adds CF conductive adhesive tape treatment process on the basis of traditional ribbon soldering, which is used for peeling off CF release film and positioning interconnection ribbon, hot pressing and others, effectively avoiding warping of the IBC cell caused by high temperature.