Warehouse Logistics Automation Knowledge Base - Automatic Sorting Equipment

Sorting refers to the process of picking and distributing items according to certain rules. In the case of large cargo flow, sorting often needs a large human resource. Taking the express distribution center or branches as an example, the human resource directly related to the sorting operation accounts for about half of the total. The sorting operation time accounts for about 30% ~ 40% of that of the whole transfer center, and the sorting cost accounts for 40% of the total cost of the transfer center.

Therefore, the reasonable introduction of automatic sorting equipment to relieve the pressure on operation personnel has become an effective way for enterprises to transform from labor-intensive way to technology-intensive way.

According to the cargo type, flow rate, sorting site area and other factors, automatic sorting equipment features various forms and operation modes.

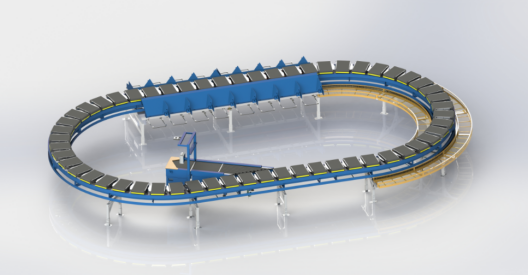

Cross Belt Sorting system

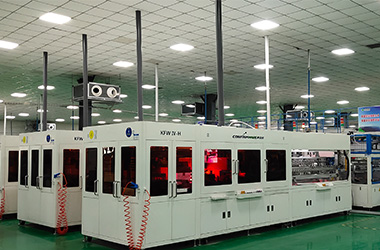

It is composed of conveyor, loading table, sorting tray, code reading and weighing system, video coding system, unloading system and so on. After the sorting tray is transported to the designated position through the conveyor line, the tray automatically drives the goods to be distributed to the corresponding chutes.

Based on many years of mature technology accumulation and development, cross belt sorting system can deal with the delivery and sorting of packages in large quantities for a long time, and has been widely used in all major warehouses and express centers.

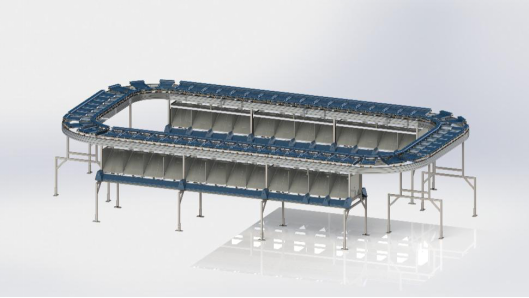

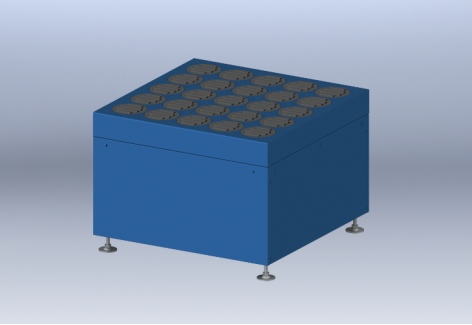

Tilt Tray Sorting

The trays are used as the sorting carrier, and after the trays are moved to the designated position, the goods are distributed by one-side or double-side tilting. The tilt tray sorting machine can handle items of various sizes and shapes stably and reliably, and its cost is relatively low.

Oblique Balance Wheel Sorter

Oblique Balance Wheel Sorter is mainly composed of conveying roller, synchronous steering controller, transmission device, rack and so on. It is commonly used in the process of parcel sorting, such as splitting, merging, rectifying, revolving, separating and conveying, etc., and is also suitable for the sorting of large special-shaped items.

Slider Sorting

Consisting of plate conveyor, slider, switch and other mechanisms, slider sorting system can distribute goods to different chutes or path through the sliders according to the command of the control system.

Sliding Shoe Sorting

In the sliding shoe sorting system, a conveyor belt line is used as the main transmission carrier, and a stretchable device capable of rotating and swinging or pushing is arranged along the chutes or the diversion paths. The device is activated when the items run in position, and the items are pushed to the corresponding chutes or paths. This sorting system is mainly used to sort large items.

The sorting equipment can be arranged in single way or multiple ways according to different application scenarios, so as to act as the most suitable and efficient automatic sorting system for the users.